A guide to Revenue Operations

(aka RevOps)

Turn your entire business into a well-oiled revenue-generating machine

No time to read now?

For many contract manufacturers, operational departments like production and supply chain work in seamless harmony, honed by the necessity of tight margins and complex production schedules. However, the same level of synchronisation might not extend to customer-facing functions like sales and marketing or operational tasks such as handling the bill of materials or managing production schedules.

Their marketing campaigns may not fully resonate with the precise customer needs identified by sales, sales teams might not have instant access to the latest marketing insights, and customer service could be more reactive than proactive in nurturing client relationships. Imagine if your sales, marketing, and customer service teams could operate with the same precision and efficiency as your manufacturing lines—coming together to drive growth and strengthen partnerships.

That's where RevOps comes into play, offering a framework to align every facet of your business towards unified revenue goals. With RevOps, sales, marketing and customer service can become as efficient and smooth-running as the internal processes on the manufacturing side.

What is RevOps?

Revenue Operations (RevOps) is a strategic business approach that unifies various business functions—such as sales, marketing, and customer success—into a single, cohesive framework. Its purpose is to optimise how revenue is generated, managed and sustained across an organisation. By eliminating departmental silos and fostering alignment, RevOps streamlines processes from initial client engagement through production and well-beyond delivery to maximise profitability and deliver a seamless customer experience.

Why is RevOps important in contract manufacturing business operations?

Many contract manufacturers today face inefficiencies that hinder their competitive edge. These inefficiencies often stem from delays caused by miscommunication between sales and production teams, for example, leading to bottlenecks in project timelines. Additionally, scaling operations for large orders presents significant challenges, such as maintaining quality standards, synchronising supply chains, and managing resource allocation effectively.

This is where RevOps comes in. By centralising data and aligning processes across production and customer success teams, RevOps creates a unified revenue ecosystem that ensures transparency and coordination. For example, improved data sharing between sales and production teams eliminates miscommunication and ensures seamless integration between sales forecasts and production schedules, avoiding bottlenecks that affect delivery lead times.

Maintaining ISO certifications or meeting other regulatory standards also often requires precise data management and coordination across teams, which RevOps facilitates by streamlining compliance processes.

Similarly, it facilitates the integration of automation tools and standardised workflows, crucial for scaling operations without sacrificing quality and supporting lean manufacturing principles by streamlining workflows and reducing waste.

By addressing these pain points, RevOps enhances operational efficiency and empowers your teams to meet customer demands promptly, optimise margins, and maintain your strategic advantage.

What does this integration look like?

As the backbone that connects sales, marketing, and customer support, RevOps ensures every business function works towards the same objectives with a shared understanding. This integration is achieved through:

Data unification: Centralising data from ERP systems, production schedules, and quality control reports creates a single source of truth for manufacturing teams. This comprehensive view allows them to monitor production timelines, track inventory levels, and analyse quality metrics effectively, resulting in actionable insights and data-driven decision-making.

Process standardisation: Establishing consistent processes across teams reduces inefficiencies and creates a smoother workflow. Standardising key manufacturing operations such as order processing, engineering change orders, and compliance checks ensures that all departments align with production goals and regulatory requirements, minimising errors and delays.

Technology alignment: RevOps leverages shared technology stacks, including CRM systems, Manufacturing Execution Systems, and Supply Chain Management tools, to streamline and improve collaboration. By integrating these manufacturing-specific technologies, you can enhance production efficiency, optimise resource allocation, and ensure on-time delivery, driving overall operational success.

Key components of RevOps

The core components of RevOps are 1) Sales Operations, 2) Marketing Operations, 3) Customer Success Operations, and 4) Data Analytics. Let’s look at how each component contributes to business success and some best practices for managing them effectively.

1. Sales Operations

Sales operations in the contract manufacturing sector involve streamlining complex sales processes, managing advanced sales tools, and providing robust support to sales teams. This enables them to focus on building relationships and closing deals. This function also includes managing CRM systems, handling pipeline and territory management, forecasting sales, and optimising processes.

In contract manufacturing, where sales cycles are often longer and involve multiple stakeholders, Sales Ops plays a critical role in managing intricate quotations, custom proposals, and detailed technical evaluations. By facilitating seamless collaboration between sales and engineering teams, Sales Ops ensures technical requirements are accurately communicated and addressed early in the sales process. This coordination reduces delays and increases the likelihood of proposal acceptance. A well-organised sales operation reduces administrative burdens on sales representatives, freeing them to focus on customer engagement. The result is improved productivity, shorter sales cycles, higher win rates, and ultimately, increased revenue for the business.

Sales Ops best practices

- Standardise sales processes: Develop consistent sales processes tailored to the manufacturing sales cycle, with clear guidelines for each stage. In contract manufacturing, these stages may include conducting initial feasibility studies, coordinating prototype development, managing engineering change requests, and ensuring compliance with regulatory standards. Standardising these steps ensures all sales representatives adhere to established protocols, making it easier to measure performance and identify areas for improvement.

- Optimise CRM utilisation: Maintain accurate and up-to-date CRM data while leveraging automation to minimise manual data entry and improve efficiency. Ensure the CRM system integrates with production and inventory systems to provide sales with real-time insights into production schedules, inventory levels, and capacity planning, enabling them to effectively align sales commitments with manufacturing capabilities.

- Make forecasting data-driven: Utilise historical data, market trends, and customer demand patterns to create accurate sales forecasts. Incorporate critical manufacturing considerations, such as supply chain dynamics and production lead times, into the forecasting process. This facilitates achievable sales targets, optimises resource allocation, and ensures that sales commitments are aligned with the your manufacturing and delivery capabilities.

2. Marketing Operations

Marketing operations in the contract manufacturing sector focus on managing and optimising strategies, campaigns, and technologies to generate high-quality leads and nurture prospects through the buyer's journey. They incorporate specialised tactics to target key sectors effectively, such as automotive, aerospace, and MedTech.

Examples include attending trade shows to showcase capabilities, publishing thought leadership articles in industry journals, and engaging in Direct outreach to key OEM accounts with tailored proposals aligned to their technical specifications.

When marketing operations are well-executed, strategies become data-driven and measurable, directly contributing to revenue growth. This approach improves lead quality, aligns marketing efforts with sales goals, and enhances ROI by ensuring marketing spend is directed towards high-impact activities.

Marketing Ops best practices

- Integrate marketing automation tools: Automation enhances efficiency and scalability, but fostering personalised relationships with decision-makers is critical in contract manufacturing. Use marketing automation tools that support ABM and enable personalised content delivery tailored to the specific challenges and needs of high-value accounts.

- Align with sales: Regular communication with sales teams helps ensure marketing campaigns target the right audiences and that a consistent definition of 'qualified lead' is applied. Build Ideal Customer Profiles (ICPs) that incorporate factors like industry sector, company size, and unique manufacturing requirements. These help align marketing and sales efforts, fostering a more focused approach to generating high-quality leads.

- Measure and optimise performance: Track KPIs like lead conversion rates, cost-per-lead, and engagement metrics to continuously evaluate and enhance marketing campaigns. In a contract manufacturing context, metrics such as the time to convert leads into technical discussions or the success of campaigns in securing meetings with decision-makers can offer valuable insights to guide future strategies.

3. Customer Success Operations

Customer success operations in contract manufacturing encompass post-sale activities like key account management, onboarding, and ongoing support. These functions ensure timely delivery, adherence to quality standards, and consistent communication with customers about project status.

In contract manufacturing, customer success involves managing complex and often long-term contracts. This includes efficiently handling change orders to minimise disruptions and maintaining flexibility to adapt to evolving customer needs.

When executed effectively, customer success operations lead to increased customer satisfaction, improved renewal rates, and reduced churn. Additionally, by fostering a deep understanding of customer needs, these operations create opportunities for cross-selling and upselling, maximising both customer lifetime value and net revenue retention rates.

Customer Success Ops best practices

- Create a customer journey map: Develop a detailed journey map outlining the entire lifecycle, from acquisition to offboarding. Include critical milestones such as production ramp-up, quality audits, and regular business reviews to ensure alignment with client expectations. Mapping these touchpoints enables proactive engagement, allowing teams to anticipate customer needs and deliver consistent value.

- Implement a consistent customer feedback loop: Establish a structured feedback mechanism to gather customer insights through surveys, performance reviews, or direct conversations. In contract manufacturing, this feedback can highlight delivery timeliness, adherence to quality standards, or responsiveness to change orders. Promptly addressing these issues fosters trust and strengthens long-term partnerships.

- Leverage customer health scores: Develop customer health scores to monitor engagement and satisfaction levels. Incorporate metrics like adherence to delivery timelines, frequency of communications, and responsiveness to support requests. Use these scores to identify at-risk accounts early and implement corrective actions, such as additional support during production challenges or enhanced communication during critical project phases.

- Streamline compliance requirements: Implement workflows that prioritise adherence to regulatory compliance, such as regular quality audits and document tracking, ensuring certifications like ISO 9001 are maintained and readily available for clients and regulators to review.

4. Data Analytics

Data Analytics in RevOps involves gathering, analysing, and leveraging data from diverse sources, including CRM systems, marketing platforms, customer feedback tools, and manufacturing-specific data like production metrics, quality control statistics, and supply chain performance. This integrated approach provides actionable insights that underpin all RevOps activities by enabling performance measurement, trend identification, and strategic decision-making.

You can gain a holistic view of revenue operations by integrating operational data with sales and marketing data. This uncovers inefficiencies to optimise strategies and align production capabilities with customer demand. This comprehensive data approach also highlights growth opportunities and enhances profitability while enabling you to adapt swiftly to market changes.

Data Analytics best practices

- Centralise data sources: Centralising data from production metrics, quality audits, and supply chain reports ensures a unified view across manufacturing operations. Ensure the data warehouse includes manufacturing execution data (MES), inventory levels, and production timelines. This integration supports a detailed operational efficiency and profitability analysis across the value chain.

- Implement real-time reporting: Use dashboards and automated reporting tools to deliver insights into critical metrics like production lead times, on-time delivery rates, and sales performance. Real-time visibility helps teams promptly identify and respond to performance deviations, minimising downtime and improving responsiveness to customer needs.

- Invest in advanced analytics tools: Feed centralised data into AI and machine learning systems to enable predictive analytics and uncover deeper insights. For example, these tools can analyse patterns in customer behaviour, forecast demand based on historical trends and market conditions, and predict future revenue opportunities. This empowers proactive decision-making to stay ahead of industry shifts.

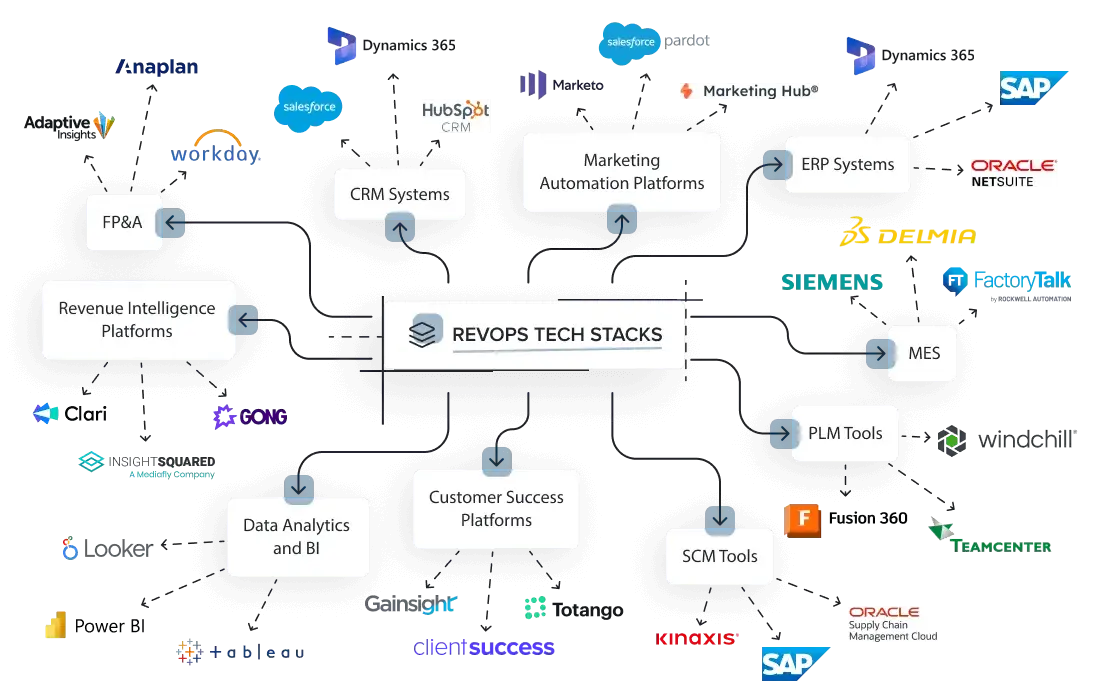

RevOps tools and software

With the right tools and technology, businesses can optimise their RevOps processes, enhance data visibility, and drive efficiency across the entire revenue cycle. Here are the essential RevOps tools and software you need, their benefits, and key considerations for selecting the right solutions for your business.

1. Customer Relationship Management (CRM)

Systems CRM systems remain essential for RevOps, providing a centralised platform to manage customer interactions, track sales activities, and monitor the sales pipeline. For contract manufacturers, they can also track customer project statuses, manage quotes, and ensure seamless communication between sales and operations.

Benefits:

- Centralises customer and project information, accessible across teams.

- Provides visibility into sales pipelines and order fulfilment.

- Automates tasks like follow-ups and data entry, improving efficiency.

- Offers reporting and analytics to provide insights into sales performance and customer behaviour.

Examples: Salesforce, HubSpot CRM, Microsoft Dynamics 365

2. Marketing Automation

Platforms Marketing automation tools streamline lead generation and nurturing but must accommodate the complex B2B relationships in contract manufacturing. Platforms should support ABM for targeting high-value OEM accounts and creating tailored campaigns.

Benefits:

- Enhances lead scoring and qualification, ensuring better sales handoffs.

- Automates repetitive tasks, saving time for custom account strategies.

- Provides analytics for campaign performance and ABM effectiveness.

Examples: Marketo, HubSpot Marketing Hub, Pardot

3. Enterprise Resource Planning (ERP) Systems

ERP systems are critical for contract manufacturers, integrating key business processes like order management, inventory tracking, production scheduling, and financial planning.

Benefits:

- Provides a unified platform for managing operations, sales, and finances.

- Enhances visibility into production and delivery timelines.

- Supports better coordination between departments to ensure timely fulfilment.

Examples: SAP, Oracle NetSuite, Microsoft Dynamics 365 ERP

4. Manufacturing Execution Systems (MES)

MES tools manage shop-floor activities, enabling real-time monitoring of production processes and ensuring defined quality standards are consistently met.

Benefits:

- Provides real-time visibility into production progress and bottlenecks.

- Ensures adherence to quality control and compliance requirements.

- Links directly with CRM and ERP systems to align production with customer demand.

Examples: Siemens Opcenter, Rockwell FactoryTalk, Dassault Systèmes DELMIA

5. Product Lifecycle Management (PLM)

Tools PLM tools are vital for managing product development processes, especially when dealing with prototypes, engineering changes, and technical specifications.

Benefits:

- Tracks product designs and revisions to ensure accurate production.

- Facilitates collaboration between engineering and production teams.

- Supports faster time-to-market for new product introductions.

Examples: Autodesk Fusion 360, PTC Windchill, Siemens Teamcenter

6. Supply Chain Management (SCM)

Tools SCM platforms optimise procurement, logistics, and supplier relationships, ensuring a smooth supply chain that supports operational goals—especially important for mitigating risks and knock-on effects associated with supply chain disruptions.

Benefits:

- Provides insights into supplier performance and material availability.

- Improves inventory management and reduces lead times.

- Supports demand forecasting and alignment with production schedules.

Examples: Oracle SCM Cloud, Kinaxis RapidResponse, SAP Integrated Business Planning

7. Customer Success Platforms

Customer success tools tailored for contract manufacturing should track project delivery timelines, manage change orders, and facilitate long-term relationship management. They help track customer health, manage onboarding, and identify expansion opportunities by monitoring usage patterns, support interactions, and satisfaction levels.

Benefits:

- Provides visibility into project health and delivery milestones.

- Automates workflows for handling customer updates and change requests.

- Enhances collaboration between customer success and operational teams.

8. Data Analytics and Business Intelligence (BI)

Tools BI tools are essential for analysing operational and revenue data. In contract manufacturing, they should integrate production, quality, and financial data to offer actionable insights.

Benefits:

- Centralises CRM, ERP, MES, and SCM systems data for comprehensive analysis.

- Offers real-time dashboards for key metrics like production efficiency and revenue performance.

- Supports predictive analytics to identify risks and opportunities in operations and sales.

Examples: Tableau, Power BI, Looker

9. Revenue Intelligence Platforms

Revenue intelligence platforms offer AI-driven insights into pipeline health and sales activity. For contract manufacturers, they can integrate with operational data to better predict revenue outcomes based on production capacity. Integrating quality management systems (QMS) with BI tools also ensures that production consistently meets regulatory and customer quality standards.

Benefits:

- Provides visibility into the alignment of sales commitments with production capabilities.

- Leverages AI to uncover trends in customer behaviour and deal health.

- Enhances collaboration between sales, operations, and finance teams.

Examples: Clari, InsightSquared, Gong

10. Financial Planning and Analysis (FP&A)

Tools FP&A tools ensure that revenue goals align with financial and operational capabilities, supporting strategic planning in the manufacturing context.

Benefits:

- Facilitates alignment between revenue forecasts and operational budgets.

- Supports scenario planning to evaluate different production and sales strategies.

- Enhances collaboration between finance, sales, and operational teams.

Examples: Adaptive Insights, Anaplan, Workday

Guidelines for selecting the right RevOps tools

Selecting the right RevOps tools can be challenging, given the variety of options available on the market. Here are some criteria to consider when evaluating tools for your organisation:

- Integration capabilities: Ensure the tools can seamlessly integrate with your existing manufacturing systems like ERP and MES.

- Scalability: Choose tools that can handle increased production volumes and additional manufacturing sites when you need to scale operations and production.

- User adoption and training: Consider how user-friendly the tools are and the level of support and training offered. High adoption rates across teams ensure the tools are used effectively.

- Customisation and flexibility: Look for customisable tools to fit your workflows and processes. This will enable you to tailor the platform to your unique RevOps strategy.

- Industry compliance: Select software that supports compliance with industry-specific regulations and standards.

- Cost and ROI: Evaluate the total cost of ownership, including licensing, implementation, and ongoing support fees. Choose tools that offer the best ROI based on your revenue goals and budget.

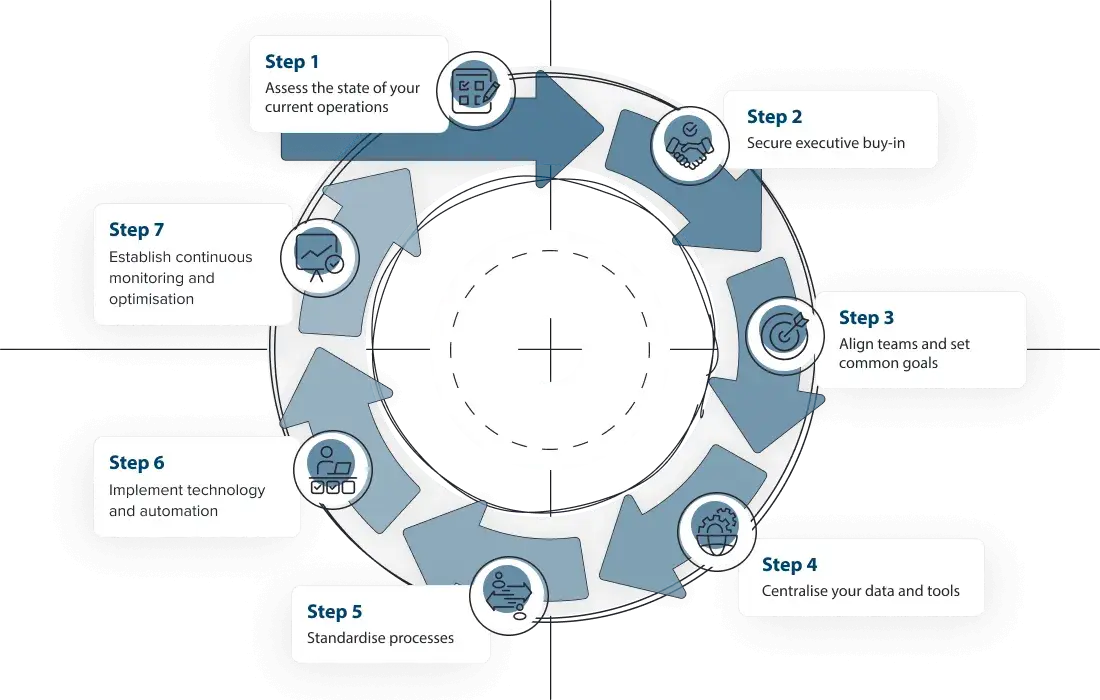

Implementing RevOps in your business

Implementing RevOps successfully in a contract manufacturing environment requires careful planning, collaboration, and a deep understanding of industry-specific challenges. In this section, we’ll guide you through a step-by-step process for integrating RevOps, address common challenges such as aligning RevOps with existing production workflows, ensuring data accuracy across complex supply chains, and onboarding teams to new systems tailored to manufacturing operations.

Step-by-step guide to implementing RevOps

Step 1: Assess the state of your current operations

Before implementing RevOps, evaluate the current state of your revenue-generating functions, including sales, marketing, and customer success. Understand how these teams operate, their technologies, and how well they collaborate. Identify inefficiencies, bottlenecks, and areas of misalignment. Include production planning, inventory management, and supplier relationships in your assessment to ensure a comprehensive understanding of operations.

- Conduct internal audits to assess process gaps.

- Gather data on current workflows, systems, and key performance metrics.

- Identify silos between departments that hinder collaboration.

Step 2: Secure executive buy-in

Strong leadership support is required for RevOps to be successful. Secure executive buy-in by presenting a compelling case highlighting the benefits of RevOps, such as increased efficiency, improved revenue growth, and better customer experience.

- Create a detailed proposal outlining the business benefits of RevOps.

- Propose key performance indicators and expected outcomes, such as revenue growth, cost savings, and improved alignment.

- Engage stakeholders across departments to ensure cross-business alignment on RevOps goals.

Step 3: Align teams and set common goals

RevOps works best when all revenue-focused teams share a unified vision and common objectives. Establish clear revenue goals and ensure each department is aligned on how they will contribute to achieving them.

- Develop shared KPIs and performance metrics across sales, marketing, and customer success teams.

- Hold cross-functional workshops to encourage collaboration and set expectations for alignment.

- Ensure each team understands their role in the customer journey and the revenue cycle.

Step 4: Centralise your data and tools

A key pillar of RevOps is data centralisation. Take the time to gather data from different teams into a single platform, such as by integrating CRM systems, marketing automation tools, and customer success platforms. This provides a holistic view of your revenue operations, what the data reflects, and where it is utilised.

- Audit and centralise your tech stack to ensure data integration between systems; don’t be scared to cull redundant tools if necessary.

- Implement or upgrade your CRM to act as the central source of data truth.

- Invest in data analytics tools to track and report on unified metrics in real-time.

Step 5: Standardise processes

To achieve efficiency and scalability, it’s important to standardise processes across all revenue-generating teams. This includes everything from lead qualification and sales pipeline management to customer success activities like onboarding and retention. Ensure everyone knows how processes flow between functions and that teams have a shared understanding of key process steps, e.g. how to qualify a lead.

- Create standardised workflows for lead generation, sales handoffs, and customer support.

- Document and share processes to ensure consistency across teams.

- Automate repetitive tasks where possible using tools like CRM systems and marketing automation platforms.

Step 6: Implement technology and automation

Overlapping somewhat with the previous two steps, once processes are standardised, it’s time to implement technology to automate repetitive tasks and streamline operations. This includes automating marketing campaigns, sales follow-ups, customer onboarding, and other routine processes that are typically time and resource-intensive for teams.

- Deploy automation tools such as marketing automation platforms, sales engagement software, and customer success platforms.

- Use AI-powered analytics tools to forecast revenue trends and monitor performance in real-time.

- Continuously refine and optimise automation to meet evolving business needs.

Step 7: Establish continuous monitoring and optimisation

RevOps is an ongoing process that requires continuous monitoring and improvement. Regularly review performance metrics, identify areas for improvement, and adjust strategies accordingly. Ensure that teams stay aligned and processes remain efficient.

- Set up regular performance reviews and team check-ins to assess progress.

- Monitor KPIs such as conversion rates, customer lifetime value (CLV), and pipeline velocity.

- Create feedback loops where data insights drive changes to processes, tools, and strategies.

Common implementation challenges to be aware of and solutions to try

Resistance to change

One of the most common challenges when implementing RevOps is resistance from teams used to working in departmental silos. Sales, marketing, and customer success teams may have different priorities and workflows, making it challenging to align around common goals. In manufacturing, production teams may also resist changes that could affect their established processes.

Strong communication and collaboration between teams should be prioritised early to address this. Engage them early in the process to gain their buy-in, explain the benefits of RevOps, and show how it will make their roles easier. Offer training to help teams adapt to new tools, processes, and workflows, and consider appointing a RevOps leader or team to oversee implementation and support teams through the change.

Data silos and inconsistent metrics

Many businesses struggle with fragmented data across different systems and teams. Sales may use one CRM, while marketing uses another, leading to data discrepancies that make it difficult to measure performance across functions.

While cleansing historical data may be difficult, you can mitigate this challenge as you start your RevOps journey by centralising all data into a single source of truth and integrating your CRM, marketing automation tools, and customer success platforms. This ensures all teams work from the same data and can track unified KPIs. Also establish clear data governance practices to keep data clean, accurate, and regularly updated.

Misaligned incentives

In traditional models, sales, marketing, and customer success teams often have separate incentives, which can cause misalignment when shifting to RevOps. For example, marketing may focus on generating leads while sales prioritises closing deals, and customer success focuses on retention—all without cross-functional coordination.

To address this, redefine incentives to align with overarching revenue goals. For example, structure incentives around customer lifecycle stages, such as lead generation, conversion, retention, and upselling. Encourage teams to work together toward shared KPIs, such as revenue growth or customer satisfaction, to foster a culture of unity and teamwork where everyone wins when the goals are accomplished.

Lack of expertise or resources

Implementing RevOps may require expertise in areas like data analytics, automation, and technology integration, which some businesses may lack internally. Additionally, smaller teams may feel overwhelmed by the scope of RevOps implementation.

It can help to invest in external expertise, such as hiring a RevOps consultant or working with an agency specialising in revenue operations. To make the change more manageable, start small by focusing on key areas of improvement, then scale RevOps processes as the team becomes more familiar with the framework.

Keeping teams aligned over time

Even after implementation, maintaining alignment between teams can be challenging as business priorities shift or new technologies are introduced. Regularly scheduled cross-functional meetings to review performance, realign goals, and address challenges can keep teams aligned long-term and make working together a habit. Also, real-time dashboards and reporting tools should be used to allow all teams to track progress towards shared goals.

RevOps strategies for business growth

In this section, we explore key RevOps strategies, how they propel business growth, and the metrics to quantify and track their success.

Optimising lead qualification and handoff processes

An effective lead qualification process ensures that only high-quality leads are passed to sales teams, while efficient handoffs between marketing and sales reduce friction in the buyer’s journey. For contract manufacturers, lead qualification should include assessing the technical feasibility of projects, alignment with manufacturing capabilities, and potential profitability. This may involve early collaboration with engineering teams.

Streamlined lead qualification and handoffs lead to higher conversion rates and shorter sales cycles, increasing revenue potential and improving team efficiency. By using automation tools and defined lead scoring criteria, you can qualify leads accurately and route them to the right people seamlessly.

Here are the key actions to set this strategy in motion:

- Implement lead scoring models based on data insights and input from engineering and product teams, considering criteria like engagement levels and what “best fit” looks like.

- Use automation tools to notify sales of qualified leads in real-time.

- Continuously refine qualification criteria based on feedback from sales and customer success teams.

Enhancing customer lifecycle management

Customer management through a RevOps framework maximises revenue across the entire customer lifecycle, from initial engagement to post-purchase support and upsell opportunities. By optimising customer interactions at each stage, you can reduce churn, increase customer lifetime value (CLV), and enhance overall customer satisfaction.

Here’s what to action when enhancing your customer lifecycle management:

- Develop customer journey maps to identify engagement points and potential friction.

- Use customer health scores to identify at-risk accounts and prioritise retention efforts.

- Implement automated workflows for renewals and upsell opportunities based on customer behaviour and needs.

Implementing revenue forecasting and pipeline

management Revenue forecasting and pipeline management allow for more informed strategic planning, plugging revenue gaps and sustaining growth. With RevOps, you can achieve accurate revenue forecasting and efficient pipeline management, gaining clear visibility into future revenue potential. By combining historical data, market trends, and predictive analytics, RevOps can help you optimise resource allocation and identify potential risks in your pipeline.

Important action steps for this strategy include:

- Using forecasting tools to analyse historical data and predict future revenue trends.

- Regularly monitoring pipeline health and tracking the progress of deals to prevent bottlenecks.

- Aligning resources with forecasted demand to ensure team availability and budget adequacy well ahead of time.

Metrics to measure the success of your RevOps strategies

To evaluate the effectiveness of these RevOps strategies, you should track specific metrics that reflect revenue performance, operational efficiency, and customer satisfaction.

These metrics include:

- On-Time Delivery Rate, which measures the percentage of orders delivered on or before the promised date. This metric reflects the efficiency of your production scheduling, supply chain management, and delivery processes.

- First-Pass Yield (FPY), a quality measure that calculates the percentage of products that meet quality standards without needing rework or adjustments. High FPY indicates efficient manufacturing processes and quality control.

- Overall Equipment Effectiveness (OEE) evaluates manufacturing productivity by considering availability, performance, and quality. This metric highlights how effectively equipment is used during production.

- Inventory Turnover Ratio measures how often inventory is sold and replaced over a specific period. It helps track inventory management efficiency and alignment with demand.

- Order Fulfillment Lead Time tracks the time taken from when a customer places an order to when it is delivered. This metric is crucial for assessing operational efficiency and customer satisfaction.

- Revenue Growth Rate measures revenue increase over time, providing a broad indicator of business health and the success of revenue strategies.

- Customer Lifetime Value (CLV) tracks the total revenue generated from a customer throughout their relationship with your business. It indicates the effectiveness of lifecycle management and the profitability of long-term contracts.

- Customer Retention Rate calculates the percentage of customers retained over a specific period, reflecting customer satisfaction and the effectiveness of post-sale relationship management.

- Sales Cycle Length measures the average time to close a sale, offering insights into the efficiency of the sales process and areas for potential improvement in contract negotiation and proposal handling.

- Lead-to-Customer Conversion Rate indicates the percentage of leads that convert into paying customers, showcasing the quality of lead qualification and the effectiveness of sales and marketing collaboration.

Conclusion

RevOps is a transformative approach for contract manufacturers that extends beyond production and manufacturing. It enables your business to act as a strategic manufacturing partner, aligning marketing, sales, customer success, and production teams to deliver high-quality, customised solutions.

Your marketing team gains clarity on how their efforts drive tangible sales outcomes, enabling targeted strategies that resonate with potential clients. Sales can approach every client conversation with insight and confidence, fostering trust and alignment with their needs. Customer service teams move beyond day-to-day support, nurturing deep, value-driven relationships.

By implementing the right tools, processes, and best practices while fostering a culture of collaboration around shared goals, you position your organisation to deliver customised, high-quality solutions with unmatched efficiency, building enduring partnerships and driving sustained growth.

Want to save a copy? Well send a copy direct to your inbox.